Order Sequencer

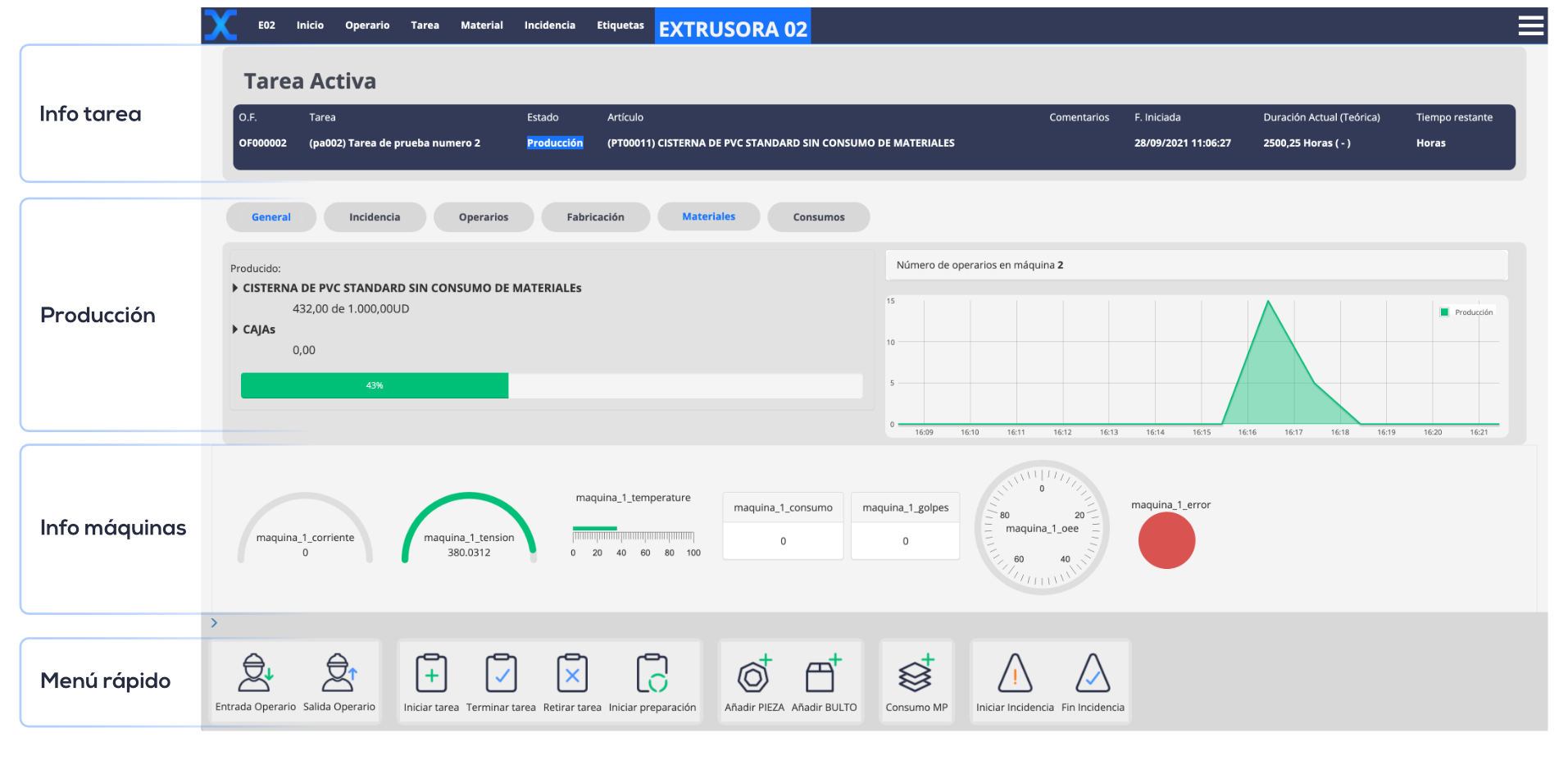

Program production with the best list of activities to be performed on machines and production lines.

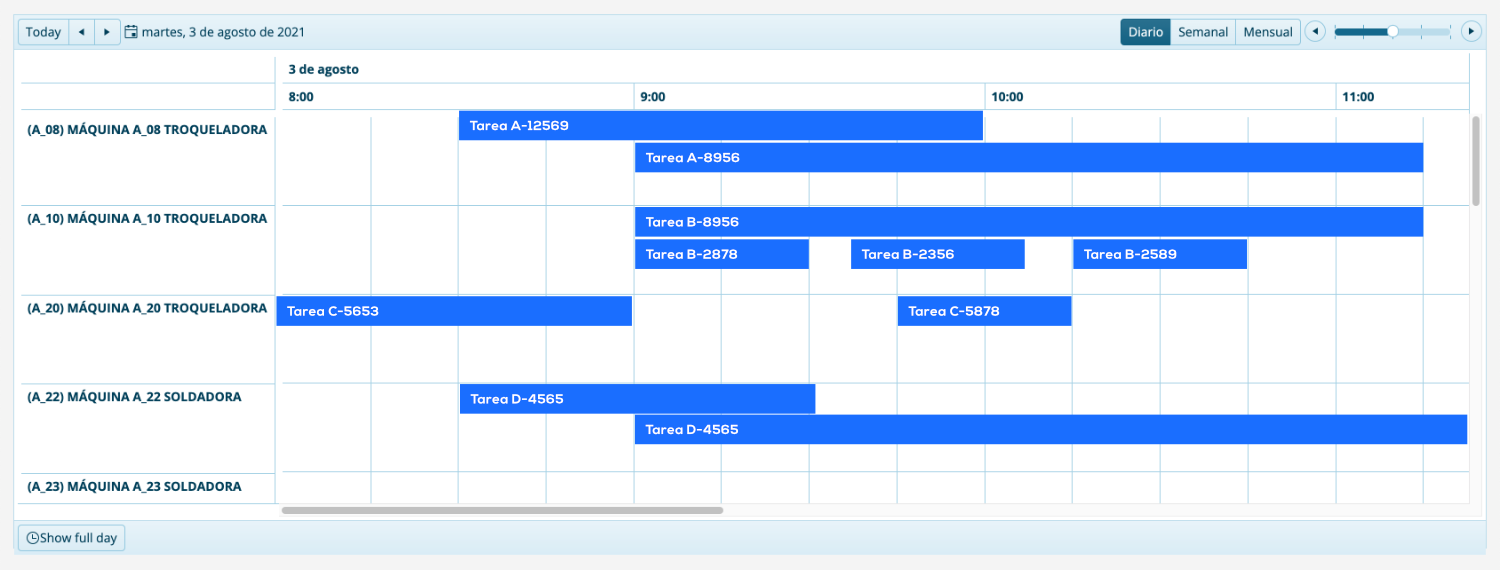

Sequence visually and easily

React to order changes and unexpected events by defining or redefining the best list of activities to be produced.

- Operators receive orders automatically on their devices.

- View tasks for each machine and those coming up.

- Make easy modifications with drag-and-drop functionality.

A Higher Level of Production

- Avoid downtime

Optimize communication on the factory floor

Manage unexprected

Optimize the operational production plan.

Immediate communication with the production plan change departmen

Improve departmenral activity effiency

Handle emergencies and unexpected requests

Reduce operational errors related to movements

Shorten setup time

Detailed Features

- Order and sequence the workload for each machine/production line visually and easily.

- Automatically send production orders to the operator.

- Locate tasks for each machine and make changes.

- Manual creation (drag and drop) based on the list of scheduled operations.

- Load profiles, calendars, and Gantt charts for machines.

- Change work sequence, start and finish dates, reassignment to alternative machines, use of alternative operations.

Frequently Asked Questions

How will it benefit my company?

INEXION MES makes it possible to automate and control all processes involved in the manufacturing of your products, significantly improving plant productivity and performance.

Who performs the implementation?

A team from Overtel is responsible for the entire process, from customer contact to on-site implementation, training, and development. For this, a Coordinator, Project Director, Implementer, and Developer are assigned, working together to ensure a successful implementation.

How long does it take?

The INEXION MES system can take approximately 2 to 3 months, but this duration may vary depending on specific case characteristics. You can book a demo to discuss your specific case

Will it adapt to my production plant?

Yes, it's a system adaptable to any type of industrial plant. Ask one of our consultants, and they will provide more specific information about your case.

.png?width=501&height=92&name=Overtel%20Logo%20Postivo%20(7).png)