Machine Monitoring

INEXION collects and sends information to machines to enable Industry 4.0 interconnectivity.

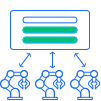

Enhanced and Visual Monitoring

Provides real-time information on the overall state of individual machines and by plant.

Estado general

Visualiza el estado general de la planta en tiempo real y ofrece el rendimiento OEE en tiempo real

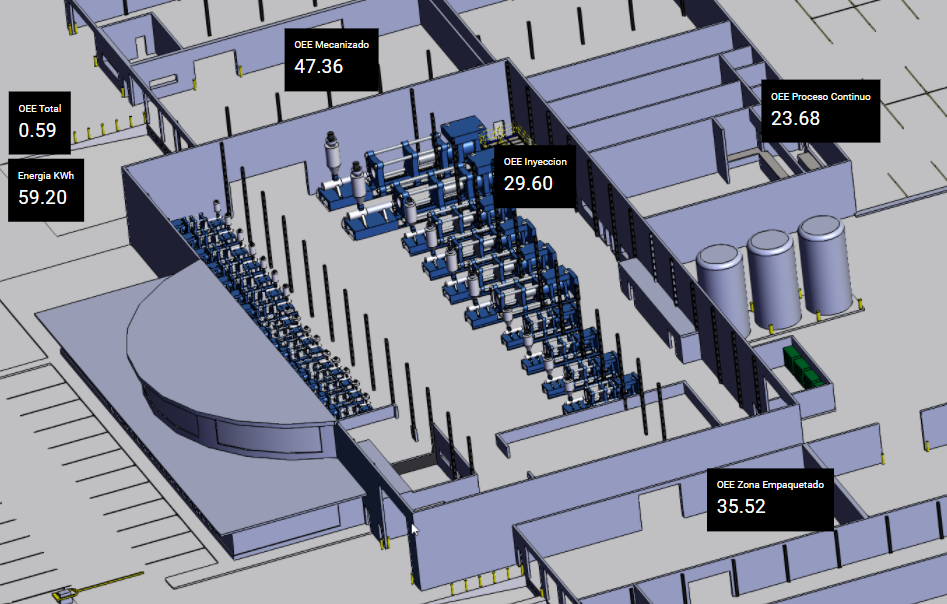

Máquinas en Planta

Adquiere directamente las señales / datos de las máquinas, visualiza el estado de máquinas por planta y OEE

Detailed Functionalities

- Production quantity counting.

- Multiplier management.

- Acquisition of the physical state of interconnected systems.

- Enrichment of the real-time updated synoptic:

- Deviation between theoretical and actual produced quantity (with respect to configurable sampling periods).

- Real-time updated relative graphical visualization (pre-alarm, out of cycle).

- Physical state (ON, OFF) graphically displayed.

- Generation of critical issues related to the "process" (intercepted by the workflow module and/or event/action engine).

- Delta "actual machine cycle compared to theoretical" exceeding a threshold.

Frequently Asked Questions

How will it benefit my company?

INEXION MES makes it possible to automate and control all processes involved in the manufacturing of your products, significantly improving plant productivity and performance.

Who performs the implementation?

A team from Overtel is responsible for the entire process, from customer contact to on-site implementation, training, and development. For this, a Coordinator, Project Director, Implementer, and Developer are assigned, working together to ensure a successful implementation.

How long does it take?

The INEXION MES system can take approximately 2 to 3 months, but this duration may vary depending on specific case characteristics. You can book a demo to discuss your specific case

Will it adapt to my production plant?

Yes, it's a system adaptable to any type of industrial plant. Ask one of our consultants, and they will provide more specific information about your case.

.png?width=501&height=92&name=Overtel%20Logo%20Postivo%20(7).png)