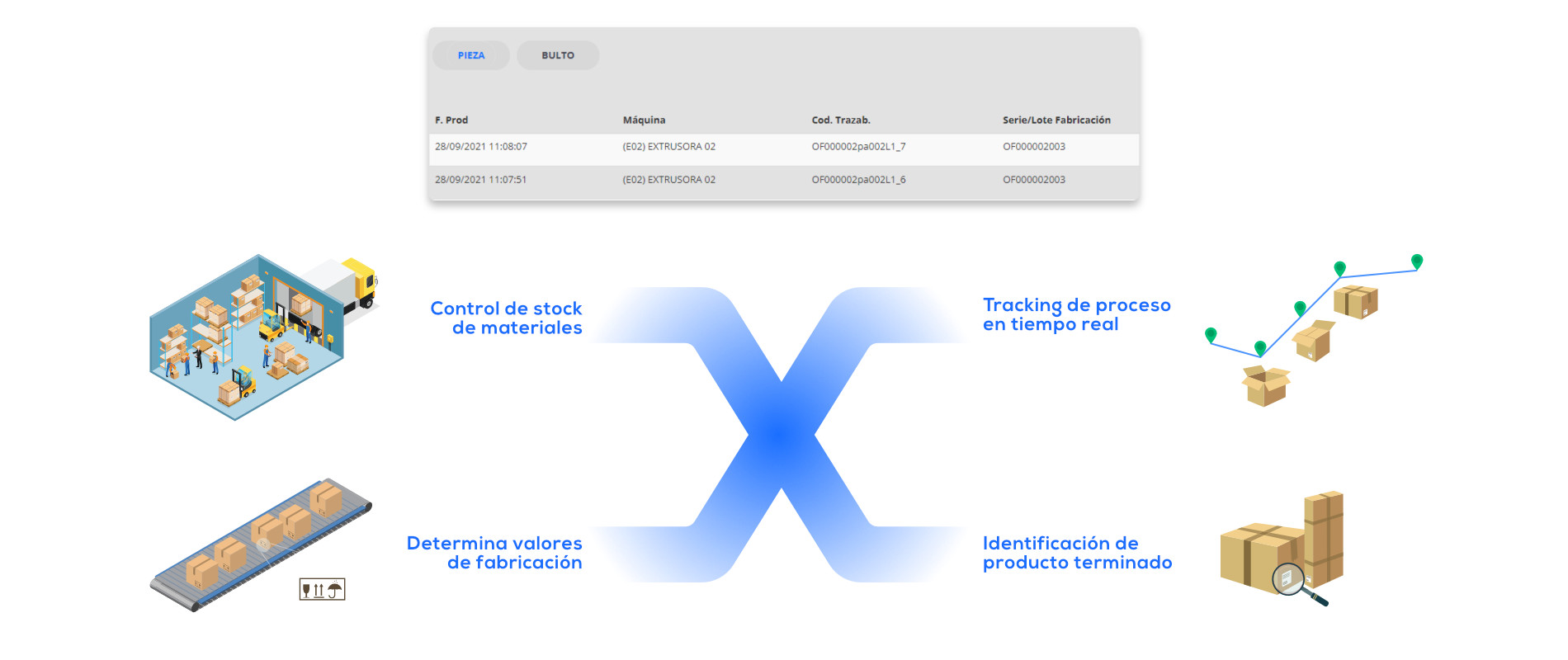

End-to-End Traceability

Collects times and quantities for complete movement management

Advanced Tracking and Precision

Controls individual materials and handling units (pallets, baskets, etc.). Manages by batch/serial number.

- Greater Inventory Accurancy

- Reduction in cost related to the non-quality of materials used.

- Facilitation and speed in quering batch links.

- Maximum content loss due to the possible withdrawal of the product from the market.

- Reduction of operational errors related to hendling

- Decrease in the number of requested declarations.

- Transparent paper trays for tracking.

- Constant knowledge of the position of each UOM (Unit of Measure).

- Traceability of raw material components and the production process.

- Simplification of operator declarations.

Detailed Functionalities

Batches:- Batch detection through barcode / data matrix / RFID readings.

- Visual chart with generated batches, batches used.

- Definition of rules for generating batch codes in entry and payment phases.

- FIFO / LIFO logical management of batches used and consumed in proportion to the completed quantity, with management of batch waste.

- Registration, typology, characteristics.

- Goods moved to/from.

- Composition/Breakdown.

- Movement between deposits and buffers.

- Physical tracking (physical location).

- Traceability: historical movements, uses, compositions, breakdowns, quality checks.

- Production declarations made on the object: automatic reconciliation of transactions with orders/operations/tasks to which the materials belong.

- Reading of codes using RFID, barcode, etc.

- Consistency checks of available items (item, order quantity, etc.).

- Object query tree - Composition lists (objects, resources, used batches) and all levels: item usage (items in which they are used).

Frequently Asked Questions

How will it benefit my company?

INEXION MES makes it possible to automate and control all processes involved in the manufacturing of your products, significantly improving plant productivity and performance.

Who performs the implementation?

A team from Overtel is responsible for the entire process, from customer contact to on-site implementation, training, and development. For this, a Coordinator, Project Director, Implementer, and Developer are assigned, working together to ensure a successful implementation.

How long does it take?

The INEXION MES system can take approximately 2 to 3 months, but this duration may vary depending on specific case characteristics. You can book a demo to discuss your specific case

Will it adapt to my production plant?

Yes, it's a system adaptable to any type of industrial plant. Ask one of our consultants, and they will provide more specific information about your case.

.png?width=501&height=92&name=Overtel%20Logo%20Postivo%20(7).png)